Summary

Please enable javascript to play this video.

| Quick Facts: Medical Equipment Repairers | |

|---|---|

|

$60,670 per year

$29.17 per hour |

|

| Associate's degree | |

| None | |

| Moderate-term on-the-job training | |

| 66,400 | |

| 13% (Much faster than average) | |

| 8,800 | |

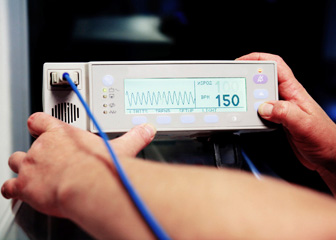

What Medical Equipment Repairers Do

Medical equipment repairers install, maintain, and repair patient care equipment.

Work Environment

Although medical equipment repairers usually work during the day, they are sometimes expected to be on call, including evenings and weekends. Because repairing vital medical equipment is urgent, the work is sometimes stressful. Those who work in a patient-caring environment are potentially exposed to germs, diseases, and other health risks.

How to Become a Medical Equipment Repairer

Employers generally prefer candidates who have an associate’s degree in biomedical technology or engineering. Depending on the area of specialization, repairers may need a bachelor’s degree, especially for advancement.

Pay

The median annual wage for medical equipment repairers was $60,670 in May 2023.

Job Outlook

Employment of medical equipment repairers is projected to grow 13 percent from 2022 to 2032, much faster than the average for all occupations.

About 7,300 openings for medical equipment repairers are projected each year, on average, over the decade. Many of those openings are expected to result from the need to replace workers who transfer to different occupations or exit the labor force, such as to retire.

State & Area Data

Explore resources for employment and wages by state and area for medical equipment repairers.

Similar Occupations

Compare the job duties, education, job growth, and pay of medical equipment repairers with similar occupations.

More Information, Including Links to O*NET

Learn more about medical equipment repairers by visiting additional resources, including O*NET, a source on key characteristics of workers and occupations.

United States Department of Labor

United States Department of Labor